All instructions and recommendations are based on the most recent information available. If you receive a printed copy of these instructions, please contact your local dealer or retailer to ensure you have the most up to date version of our installation instructions.

By starting installation of this product, you are agreeing that you have read and understand all installer/owner’s requirements and responsibilities and are aware that deviating from the instructions and recommendations in this installation guide may result in voiding the product warranty. If you need additional assistance, please contact your dealer or retailer.

Handle cartons and flooring carefully to protect the locking edge profile. Always transport and store cartons in the original packaging, neatly stacked horizontally on a smooth, flat, solid surface. Never on their sides or ends.

The product is a floating floor suitable for indoor installations only, in a controlled environment(while occupied) within the required temperature range of 55°F to 100°F (12.78°C to 38°C). Do not install outdoors. Please note that extreme variances in temperature may increase expansion and contraction not only in the flooring itself but the structure as well. Do not install fixed objects, such as cabinets, islands, wall units etc. on top of the flooring or fasten trim/molding/transition pieces directly to the floor. Please refer to our warranty for information regarding rolling loads. SPC flooring replicates the look of a natural product which has natural variations in color and texture. For best visual effect, shuffle planks from several cartons and d o not install similar boards next to one another.

Subfloor must be level, dry and free of imperfections. An uneven subfloor will make the floor feel unstable and cause premature damage and void warranty.

Please note: Additional foam is not recommended if foam is already attached to flooring.

Carefully examine the flooring prior to installation for color, finish, and quality. Do not install defective product. The factory cannot accept responsibility for flooring installed with visible defects. Prior to installation of any flooring, the installer must ensure that the job site and subfloor meet the requirements of these instructions. The factory is not responsible for flooring failure resulting from unsatisfactory jobsite and or subfloor conditions. Flooring should be one of the last items installed in any new construction or remodel project. Although flooring is waterproof it is not a moisture barrier.

Crawl spaces must be a minimum of 18”(46cm)from the ground to the underside of the joists. A ground cover of minimum 6mil black polyethylene film is essential as a vapor barrier with joints lapped 6”(15cm)and sealed with moisture resistant tape. The crawl space should have perimeter venting equal to a minimum of 1.5% of the crawl space square footage. These vents should be properly located to foster cross ventilation. Room temperature and humidity of installation area should be consistent with normal, year-round living conditions for at least one week before installation of flooring. Maintaining an optimum room temperature of 70°F and a humidity range of 30-50% is recommended. Acclimate flooring by storing the packages in the room or rooms to be covered for at least 24 hours at normal room temperature before installation.

All Subfloors must be:

•Dry (30-50% relative humidity)

•Structurally sound

•Clean: Thoroughly swept and free of all debris

•Level: Flat to 4.7mm(3/16”)per 3.3 meters (10-foot) radius

Wood subfloors must be dry and well secured. Nail or screw every 6” along joists to avoid squeaking. If not level, sand down high spots and fill low spots with a Portland Based leveling patch.

Concrete subfloors must be fully cured, at least 60 days old, and should have minimum 6-mil polyfilm between concrete and ground. Subfloor should be flat and level with 3/16”per 10’radius. If necessary, grind high spots down and level low spots with Portland leveling compound.

Ceramic Tile, resilient tile and sheet vinyl must be well-bonded to subfloor, in good condition, clean and level. Do not sand existing vinyl floors, as they may contain asbestos.

For all installation methods:

•Tape measure

•Tapping block(trimmed piece of flooring)

•Do not use with other tapping blocks. Damage will occur to SPC core.

•Pencil

•Pry bar or pull bar

•Chalk line

•Crosscut power saw

•3M Scotch-BlueTM 2080 Tape or equivalent tape

•Rubber mallet

Acceptable subfloor types:

•CDX Underlayment Grade Pl ywood (at least ” thick)

•Underlayment grade particleboard

•OSB (at least ” thick)

•Concrete slab

•Existing wood floor

•Ceramic tile

•Resilient tile & sheet vinyl

Inspection: Prior to installation, inspect planks in daylight for visible faults/damage. Check if subfloors/site conditions comply with the specifications described in these instructions. If you are not satisfied do not install and contact your supplier.

Before laying: Measure the room at right angle to the direction of the planks. For best visual effect, planks in the final row should be at least 2 inches wide (half width of the plank minimum). For this purpose, planks in the first row can be cut to smaller size.

Shuffle planks to obtain a pleasant bled of shades. Lay planks preferably following the direction of the main source of light. We recommend laying on wooden floor crossways to the existing floorboard. Planks must not be nailed or screwed to the subfloor.

Base boards and molding must not be fixed in a way which restricts the movement of the floor Do not restrict movement

1. Adjust row so end cut is not less than 8”.

2. Use shims to allow 3/8” expansion gap between the planks and the walls, or

stationary interior room objects, so there is room for normal expansion and movement.

3. Starting from the LEFT with the tongue facing the wall, carefully place the first board in place.

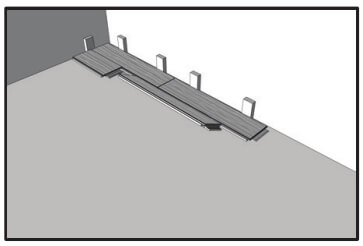

4. Align the next piece by overlapping the short end of the first board. Engage the short end at 45° angle of the tongue and grove. The board must be flat to engage completely. Tap lightly into place by using a rubber mallet and tapping block to firmly lock short end. Continue in this manner until reaching the final plank in the first row

5. Cut the final boa rd piece to length.

6. Begin the second row with the cut piece from the first row. If the cut piece is shorter than 8”(20cm), do not use it. Instead, begin with a new boa rd to the left as necessary to align the edges of the end joint of the first row. Carefully push the boa rd down until the tongue and grove lock together on the long side and ends.

7. Position the first boa rd of the second row in place by angling it up slightly, pushing forwa rd and interlocking the long side of the tongue. Slide the board to the left as necessary to align the edges of the end joint of the first row. Carefully push the boa rd down until the tongue and grove lock together on the long side and ends.

8. Install second boa rd of the second row (same as step 4 above). Slide close to the end joint without touching it. Ensure board lays flat.

9. Tap firmly but gently on end joint with a rubber mallet and tapping block to fully engage short end. Before moving on the next board, ensure the end joints are flush and tight.

10. Install the remaining boards and rows in the same manner.

11. Cut the last boa rd to size. If necessary, complete the tight fit by tapping the board into place with a pull bar.

12. Whenever practical, use cut pieces from previous rows as the starter boa rd to reduce waste.

13. Maintain 8” spacing between end joints after the first rows for best appearance.

•Maintain 3/8”expansion gap around room perimeter

•Areas over 30’long or 30’wide need transition pieces

•Non-square rooms must have expansion or transition gaps separating them

•All door options must have an expansion gap between rooms

1. The last row may need to be cut lengthwise (ripped).

2. Place the last row of planks to be fit on top the last row of installed planks. Use a piece of plank as a scribe to trace the contour of the wall.

3. Mark where the board will be cut. If the fit of the wall is simple and straight, simply measure for the correct fit and cut.

4. After boards are cut, position planks and tighten the fit using the pull bar.

1. Installation under moldings (such as door jambs)may require that the top lip of the grove on the end be reduced in size.

2. Using a small plane or knife plane, carefully shave off the ledge of the grove.

3. After the grove ledge has been trimmed, place and tighten with a pull bar to test for fit. The installer must be sure that the required expansion gap has been maintained and the flooring is not pinched.

4. If fit is not correct, re-trim as necessary.

5. Place a bead of wood glue on the bottom lip of the grove.

6. Insert the tongue into the groom and tighten the fit with a pull bar. Hold the board in place with painters’ tape(3M Scotch-Blue™ 2080 Tape or equivalent) until the glue is dry. Do not use masking tape or duct tape as they may damage the floors finish.

Use only recommended flooring adhesive over manufacturer’s recommended pl ywood substrate.

•Turn the heat off for 24 hours before, during and 24 hours after installation when installing over radiant heated subfloors

•Failure to turn the heat off may result in shortened working time of the adhesive

•Floor temperature must not exceed 85°F(30°C)

•Failure to strictly follow adhesive manufacturer’s guidelines may result in failure and void warranty

Warning: Heating mats work very well under carpet, tile and stone; however, we do not recommend having them placed directly

underneath the SPC floor. It is best to install SPC flooring over hydro-based radiant heating systems.

• Flooring should be one of the last items installed in a project. To protect the floors while other trades are finishing their work prior to final cleanup and turnover to the owner, use rosin paper and only 3M Scotch-BlueTM (or equivalent) to hold the rosin

paper to the floor (other blue tapes may damage the finish). Clean the floor thoroughly before laying the rosin paper to ensure that no debris is trapped underneath.

•DO NOT USE plastic film or other non-breathing coverings as this can cause the floor to become damaged from humidity buildups.

•Dust mop or vacuum your floor to remove any dirt or debris

•It is suggested that you buff the floor with lamb’s wool pads to remove any loose splinters, residues, footprints, etc.

•Install any transition pieces that may be needed(reducers, T-moldings, nosing, etc.).

Lasting beauty can be achieved through purchasing a quality floor covering and providing proper on-going maintenance.

•It is recommended to sweep & vacuum the area immediately after installation to remove potential debris that may harm your floor.

•Furniture should be moved onto the newly installed floor using an appliance hand truck over hardboard runways. DO NOT roll or slide them across the floor without protection.

• Avoid exposure to long periods of direct sunlight. Close blinds or drapes during peak sunlight hours. Floor covering subjected to excessive heat and light is subject to thermal degradation. Use appropriate precautions to minimize potential effects on the

floor covering.

•Oil or petroleum-based products can result in surface staining. D o not track asphalt-driveway sealer or automobile-oil drips onto the floor covering.

•Use non-staining mats. Rubber mats may discolor the floor. Wove n rugs may have dye’s that can permanently stain your flooring.

Using a non-staining padding/mat under it will help reduce that risk.

• Frequently moved furniture should be equipped with felt pads and replaced periodically to avoid scratching the floor. Heavy furniture and appliances should be equipped with non-staining large surface floor protectors. Furniture with castors or wheels must be as swiveling, large surface non-staining and suitable for resilient floors. D O N OT use ball type castors as they can damage the floor.

•Use floor protectors under furniture.

•Use walk off mats at entrances to prevent dirt and grit from being tracked on the floor.

•Sweep or vacuum the floor regularly to remove loose dirt. DO NOT use harsh cleaners or chemicals on the floor. We recommend using a pH neutral floor cleaner as required. DO NOT use abrasive scrubbing tools. DO NOT use detergents, abrasive cleanersor “mop and shine” products that contain surfactants.

•Never saturate your flooring.

•DO NOT steam clean or use steam mop on the floor.

•SPC Flooring, like other types of smooth floors, may become slippery when wet. Allow time for floor to dry after washing.

•Immediately wipe up wet areas from spills, foreign substances, or wet feet.

•High heels and spiked shoes, may mark, abrade, or otherwise damage the surface and finish of your floor. This is not a warranted condition.

For information regarding our products, and warranties please contact your supplier.

MANUFACTURED BY:

Frontier Surfaces PA LLC

3535 Walnut Street, Harrisburg, PA 17109

1-855-917-4737 | FrontierSurfaces.com

Chat now with our team

of live US-based

representatives by clicking the Chat button

in the lower left corner.